Computational Design of Self-Actuated Surfaces by Printing Plastic Ribbons on Stretched Fabric

Computer Graphics Forum (Eurographics 2022)

Links

Abstract

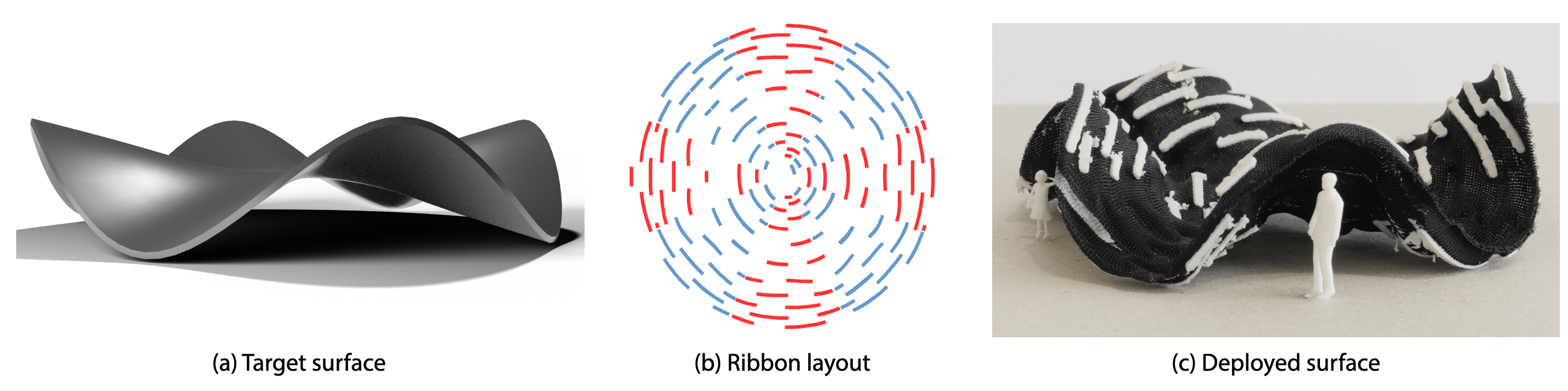

We introduce a new mechanism for self-actuating deployable structures, based on printing a dense pattern of closely-spaced plastic ribbons on sheets of pre-stretched elastic fabric. We leverage two shape-changing effects that occur when such an assembly is printed and allowed to relax: first, the incompressible plastic ribbons frustrate the contraction of the fabric back to its rest state, forcing residual strain in the fabric and creating intrinsic curvature. Second, the differential compression at the interface between the plastic and fabric layers yields a bilayer effect in the direction of the ribbons, making each ribbon buckle into an arc at equilibrium state and creating extrinsic curvature. We describe an inverse design tool to fabricate low-cost, lightweight prototypes of freeform surfaces using the controllable directional distortion and curvature offered by this mechanism. The core of our method is a parameterization algorithm that bounds surface distortions along and across principal curvature directions, along with a pattern synthesis algorithm that covers a surface with ribbons to match the target distortions and curvature given by the aforementioned parameterization. We demonstrate the flexibility and accuracy of our method by fabricating and measuring a variety of surfaces, including nearly-developable surfaces as well as surfaces with positive and negative mean curvature, which we achieve thanks to a simple hardware setup that allows printing on both sides of the fabric.

BibTeX

@article{Jourdan2022a,

title = {Computational Design of Self-Actuated Surfaces by Printing Plastic Ribbons on Stretched Fabric},

author = {Jourdan, David and Skouras, M{\'e}lina and Vouga, Etienne and Bousseau, Adrien},

year = {2022},

journal = {Computer Graphics Forum},

number = {2},

pages = {493--506},

volume = {41},

doi = {10.1111/cgf.14489},

month = may

}